Musically the era of Rock ‘n’ Roll was the 1950s but from the Highways point of view ‘rocking and rattling’ manhole covers have been experienced from the early days of the motor car, and manhole covers generally, not dissimilar to some we still see today, have been around from the latter part of the 19th Century.

Musically the era of Rock ‘n’ Roll was the 1950s but from the Highways point of view ‘rocking and rattling’ manhole covers have been experienced from the early days of the motor car, and manhole covers generally, not dissimilar to some we still see today, have been around from the latter part of the 19th Century.

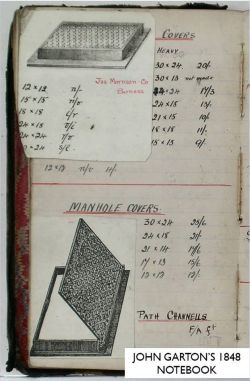

Evidence of Garton & King’s predecessors (Garton & Jarvis 1836-1863) and their manufacture of a variety of Manhole Covers of the square and rectangular type can be seen on a page from John Garton’s notebook dated 1848, seen on the right, the notebook being in our archives.

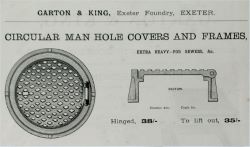

Circular Manhole Covers were produced by the Company way back in 1900 as they are advertised in their 1900 General Catalogue. Steam lorry production flourished in the 1890s. Steam road locomotives could weigh up to and in excess of 5 tons. World War 1 saw a vast increase in lorry production by Maudslay, Leyland Motors, Commer & Austin to name just a few.

Circular Manhole Covers were produced by the Company way back in 1900 as they are advertised in their 1900 General Catalogue. Steam lorry production flourished in the 1890s. Steam road locomotives could weigh up to and in excess of 5 tons. World War 1 saw a vast increase in lorry production by Maudslay, Leyland Motors, Commer & Austin to name just a few.

By 1930 there were, just counting cars, over 1 million on Britain’s roads and the weight of goods vehicles was increasing. I believe the maximum gross weight of goods vehicles allowed was by then 22 tons – manholes began to ‘rattle under the strain!'

It is said by some that square or rectangular shapes are not necessarily the best for manhole covers and that Circular (that cannot accidentally be dropped down the hole and can more easily be manoeuvred/rolled) might be a better idea.

It is said by some that square or rectangular shapes are not necessarily the best for manhole covers and that Circular (that cannot accidentally be dropped down the hole and can more easily be manoeuvred/rolled) might be a better idea.

A triangular design that prevents ‘rocking’ is one solution, the cover is supported on three points and is inherently more stable than a square or rectangular cover. Later catalogues used the same drawing but described it as “a Double Triangular Manhole Cover & Frame.”

A triangular design that prevents ‘rocking’ is one solution, the cover is supported on three points and is inherently more stable than a square or rectangular cover. Later catalogues used the same drawing but described it as “a Double Triangular Manhole Cover & Frame.”

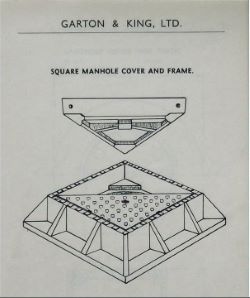

A similar type that Garton & King manufactured in large numbers is shown here.

A similar type that Garton & King manufactured in large numbers is shown here.

A recent article was discovered (May 2021) on the WREKIN Company website*. Wrekin Products are a leading UK designer, manufacturer and supplier of specialist products for the civil engineering industry; they are ‘one of the UK’s leading suppliers of ductile iron access covers and gully grates.’

A recent article was discovered (May 2021) on the WREKIN Company website*. Wrekin Products are a leading UK designer, manufacturer and supplier of specialist products for the civil engineering industry; they are ‘one of the UK’s leading suppliers of ductile iron access covers and gully grates.’

The News article referred to a problem with a Rattling Cover that was irritating the local residents in Sunderland and it appears from the image on their website* that the culprit was replaced by a square cover divided into two triangular sections and described as from their Unite D400™ Range. Shown on the right, ‘borrowed’ from their website.

*www.wrekinproducts.com

One could argue that there are similarities between the Wrekin Unite D400™ and the G&K example shown above. In fact the drawing is from a Garton & King catalogue dated sometime after 1925.

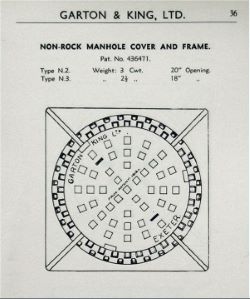

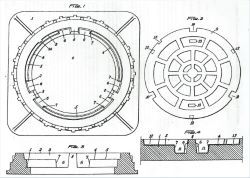

Rattling covers must have been a problem in the early 1930s so Henry Holladay decided to tackle the problem experienced with Circular Covers and submitted an Application to the Patent Office on the 19th June 1934, The Provisional Specification (No 18121/34) was for ‘A Device for the Prevention of Movement in Road Manhole Covers and Frames’.

Rattling covers must have been a problem in the early 1930s so Henry Holladay decided to tackle the problem experienced with Circular Covers and submitted an Application to the Patent Office on the 19th June 1934, The Provisional Specification (No 18121/34) was for ‘A Device for the Prevention of Movement in Road Manhole Covers and Frames’.

The Complete Specification was left on May 15th 1935 and the Complete Specification was accepted on October 11th 1935 and granted Patent No. 436471.

The specification is extremely wordy and I’ve found it difficult to condense the principle in a few sentences (it can be viewed online if you’re really interested), but it worked and they are to be seen occasionally in our roads in the Westcountry flaunting either the words ‘Patent Applied for 18121’ or, as in this photograph of one off Dunsford Hill in Exeter, ‘PAT NO 436471’.

Trawling through the lengthy text I did discover:-

“..we declare that what we claim is:-

A manhole cover and a frame therefore, wherein the cover is provided in its periphery with upwardly tapering recesses extending for the top to bottom thereof and on its underside with feet or bearing pieces between the recesses, whilst the inner periphery of the frame is provided with lugs arranged to enter the recesses in the cover and with a shelf arranged to support the bearing pieces and take the down thrust of the said cover is in position in the frame.”

And to clarify the matter further:-

“When a vehicle wheel or the like presses on the cover at points inside any of the chords there is no tendency of the cover to move owing to the fact that the bearing pieces act on the principle of the well known three-point bearing.”

Do I make myself clear?

In essence the design worked and the covers didn’t rattle or move – perhaps the diagram that accompanied the Application helps to explain the device and method used in a slightly more simplified way – or does it?

In essence the design worked and the covers didn’t rattle or move – perhaps the diagram that accompanied the Application helps to explain the device and method used in a slightly more simplified way – or does it?

May 2021

Top of page

See also:

Municipal Castings — Circular Covers — Triangular Covers

Cast Iron Cover — Gummed Up Gullies

Sitemap / Contents