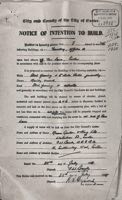

The need to relocate the Foundry from Waterbeer Street to another site came about when Exeter Town Council (as it was then) sent a Notice of Compulsory Purchase to the Company’s offices sometime in 1935 – see The Waterbeer Street Foundry page.

After much searching an area of ground at the end of Tan Lane was considered suitable. The Tan Lane site had originally been a pit, firstly where sand and clay was extracted for a small pottery (Hart & Moist) which used to be in the sheds between the Meter Works and the railway. The pit was later filled in with rejects from the pottery.

The owners of the site were the Great Western Railway. The plan shown shows that originally a footpath crossed the triangular plot and a sum of £550 was agreed for the purchase of the property, subject to the Town Council agreeing in principal to its proposed use and with the company agreeing to pay for the re routeing of the footpath, again subject to agreement with the Town Council.

After some haggling it was agreed to re route the path along the eastern (where it is to this day) boundary and the westwards along the southern boundary thus keeping the northern boundary clear should ever a railway siding be required to the works.

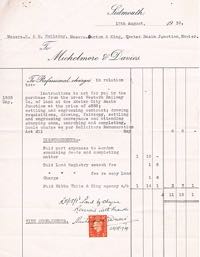

Charges for purchase of land from G.W.R. for Foundry & Works |

Letter from G.W.R. re purchase of land and matter of re-routeing footpath and agreement of purchase price |

To a foundry water and wetness are a major hazard and although it was known that the St Thomas area had floods from time to time the levels were checked and it was predicted that there could be occasions when the works might be surrounded by floods, but the site would be above this water level – this later proved, in the 1950s when the area flooded, to be correct and the works stayed above the water.

On the 28th April 1937 C.J. Newman, Exeter Town Clerk, wrote to the Company confirming that the Town Planning Committee had approved the erection of Foundry Buildings, Offices etc on the land the Company had purchased. A George Perry was appointed Clerk of Works; he was aware of the prior use of the site and ensured that all foundations were put on concrete rafts to avoid any subsidence that might occur. The Architects for the whole project was F.W. Beech A.R.I.B.A of 16 Southernhay West, Exeter.

On the 28th April 1937 C.J. Newman, Exeter Town Clerk, wrote to the Company confirming that the Town Planning Committee had approved the erection of Foundry Buildings, Offices etc on the land the Company had purchased. A George Perry was appointed Clerk of Works; he was aware of the prior use of the site and ensured that all foundations were put on concrete rafts to avoid any subsidence that might occur. The Architects for the whole project was F.W. Beech A.R.I.B.A of 16 Southernhay West, Exeter.

Site Plan - Floor-plan - Elevation-plan

M.T. Sleeman & Sons’ estimate for the erection of buildings, as per the plans, was submitted on the 19th October 1938, for £10,797.00 and was accepted.

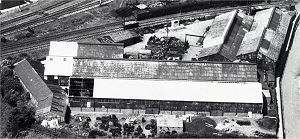

Although the siding onto the Foundry site never materialised, I have included in the group (above right) an image not seen before showing goods being loaded over the fence onto railway wagons, and (left) a very fuzzy ‘still’ from some film my father took in the late 1930s showing the site before development with the footpath running diagonally across it; you can make out a man and his dog walking along the footpath towards the camera. To get your bearings refer to the aerial photograph (top of the page) and note the position of the large house on the far side of the site which is the building surrounded by allotments to the south west of the Foundry.

Although the siding onto the Foundry site never materialised, I have included in the group (above right) an image not seen before showing goods being loaded over the fence onto railway wagons, and (left) a very fuzzy ‘still’ from some film my father took in the late 1930s showing the site before development with the footpath running diagonally across it; you can make out a man and his dog walking along the footpath towards the camera. To get your bearings refer to the aerial photograph (top of the page) and note the position of the large house on the far side of the site which is the building surrounded by allotments to the south west of the Foundry.

Minor hiccups such as drainage, width of footpath and use of a culvert were overcome and as far as can be established the construction of the Foundry, including machine shop, smithy, pattern makers shop and the offices as per the plans went ahead without significant problems being experienced, the new buildings being completed in June 1939. Removal of equipment from Waterbeer Street took several weeks.

The removal was interesting, several quotes had been sought and the cheapest turned out to be the Great Western Railway. The achieved this by having a 3-wheeled petrol driven colt to which they could attach trailers and also using horse drawn flat carts. The point being that for many items the time involved was mostly in loading and unloading so the mechanised unit could serve three trailers, two loading/unloading, one in transit, and while the carts took longer for the journey the cost of standing time was so much less it saved more than the extra time in transit, also the uphill part was with the cart unloaded. It was at the same time that the company had opened a Showroom in Queen Street at the (then) new Central Station where it remained until 1957 when it relocated to 19 North Street (where it is still.)

The removal was interesting, several quotes had been sought and the cheapest turned out to be the Great Western Railway. The achieved this by having a 3-wheeled petrol driven colt to which they could attach trailers and also using horse drawn flat carts. The point being that for many items the time involved was mostly in loading and unloading so the mechanised unit could serve three trailers, two loading/unloading, one in transit, and while the carts took longer for the journey the cost of standing time was so much less it saved more than the extra time in transit, also the uphill part was with the cart unloaded. It was at the same time that the company had opened a Showroom in Queen Street at the (then) new Central Station where it remained until 1957 when it relocated to 19 North Street (where it is still.)

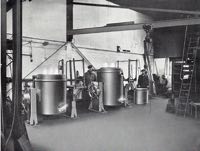

Operations at the new foundry commenced in late July, early August and the new cupola being put to its first use on or before the 19th August 1939.

It has to be said that coverage of the activities of the foundry from September 1939 through to the end of the War can be best described as sparse. Chapter 8 of Golden Hammer manages to sum up the commercial activities during that period in one paragraph. There are few sources available to glean further information from. Dad’s personal notes do elaborate on the requisitioning of part of the premises.

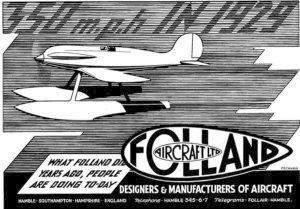

Being in new premises, various ministries kept looking at us for dispersal of other factories. Eventually they decided that Folland Aircraft of Hamble, Hants should take part of the site... This relieved us of fire watching, as they had a night shift. They made aeroplane wings. They were in occupation at the time of the Blitz on May 3 - 4 1942 (on Exeter). The raid was prolonged and severe, fortunately the works only suffered damage from shrapnel and was quickly repairable. One unexploded bomb was later found in the embankment of the railway, not far from the foundry site and had it gone off the works would have suffered considerably.

At that time the warehouse for the heating and plumbing side of the business occupied much of the machine shop building. To make room for Follands and still continue working a new ‘temporary’ warehouse was hastily constructed beyond the end of the foundry building using G & K’s own labour and materials - a corrugated iron roof on trusses of welded tube. It remained in use right up to the final closure of the Tan Lane site.

Throughout the war the works operated without interruption, however the foundry of F L Parkin in Bonhay Road, Exeter were not so fortunate and were completely destroyed, as mentioned in this extract from Dad‘s typed notes:

A little bit more information may be gleaned from this extract from Parkin‘s own History:

The Parkin intention was to rebuild the bombed foundry on its original site, along lines already outlined before the war. In the meantime, an arrangement was agreed with the Exeter foundry Garton & King, based on Parkin rental of Garton & King facilities. Castings were produced from Parkin patterns and were charged on the basis of weight. This arrangement alleviated Parkin production problems, at least in the short term. The advantage for Garton & King was that it provided an additional source of revenue at a time when their own facilities in their new larger foundry were underused. Unlike Parkins, their work was not essential to the war effort and they suffered a greater loss of manpower to conscription. This, and probably declining domestic markets in the war years, resulted in their new cupola running at significantly lower capacity than would otherwise have been the case.

The arrangement continued until 1946, when Garton & King‘s business increased and they needed full use of their facilities. They took over all of Parkin's skilled moulders on the basis that they could return to Parkins once the new foundry was rebuilt. It never was rebuilt and the Parkin men became permanent employees of Garton & King. This perhaps represents the real benefit of the agreement to Garton & King. However it was not without benefit to the Parkin firm. Without the foundry, and with little idea of the future direction of the firm, it would have had no alternative but to make its workforce redundant. Garton & King continued to manufacture Parkin castings until the early 1950s. There are no details to suggest the volume of work cast, although oral history sources suggest this was limited.

Extracted from the Parkins Company History.

The only other source that gives any indication of work carried out during the war can be gleaned from Foundry Order Books – an image is shown for a requirement for parts for the Beaufighter Aircraft and much sub contract work was carried out by the Company for W H Bird & Sons, St Phillips, Bristol.

In an interview Dad was once reported as saying that “During the second world war we made parts for tanks and other armoured vehicles and for some of the landing craft used in Malaya.”

Left: Bristol Beaufighter. Right: Advert for Bird’s Gears, Bristol (from Grace's Guide to British Industrial History') |

Although usually not particularly newsworthy, the Tan Lane Foundry did get itself into the local paper on two occasions.

The first (on the left) was a report of certificates being awarded to three men who in June 1955 had administered timely first aid to men who had received severe electric shocks when the jib of the crane unloading a large casting destined for Garton & King's machine shop accidently got too close to an overhead power line.

Because of the low railway bridge over Tan Lane, large loads had to approach G & K’s Tan Lane works through the adjacent council yard, which had a back entrance onto the Marsh Barton trading estate. The Tan Lane works had limited yard space and access. On this occasion a crane and space to manoeuvre were required, so the operation took place in the council yard. Two of the injured men, Harold Williams (who appears on the Wheels and Gears page) and Maurice Prout, were fitters/turners from G & K’s machine shop; and one of the 3 first-aiders receiving the award, W H ('Bill') Pitts, was G & K’s long-serving Maintenance Engineer. The other names have not been found in the company records - the group involved would have included the crane and lorry crew, and maybe others assisting.

The second report (right) was some years later (mid 1970s) when during maintenance work over a weekend a fire started in the single storey building housing the tar-filled trays in which the municipal castings destined for use in the roads were dipped. Luckily the fire was extinguished before it could reach the adjacent office area! (photo)

Recently unearthed amongst the paperwork which I have accumulated over some sixteen years, are these three unpretentious documents. The first (Letter 1) is dated the 15th March 1974 and it notifies foundry customers that the purchase price of Foundry Coke (as used in the cupola) was scheduled to rise and the rate was to be increased by £8.25 per (imperial) ton from the 17th of March in that year. The need to recover this increase was imperative, and as a result the surcharge then being levied was to increase from £2.20 to £4.10 per ton for all deliveries after 17th March 1974.

|

|

|

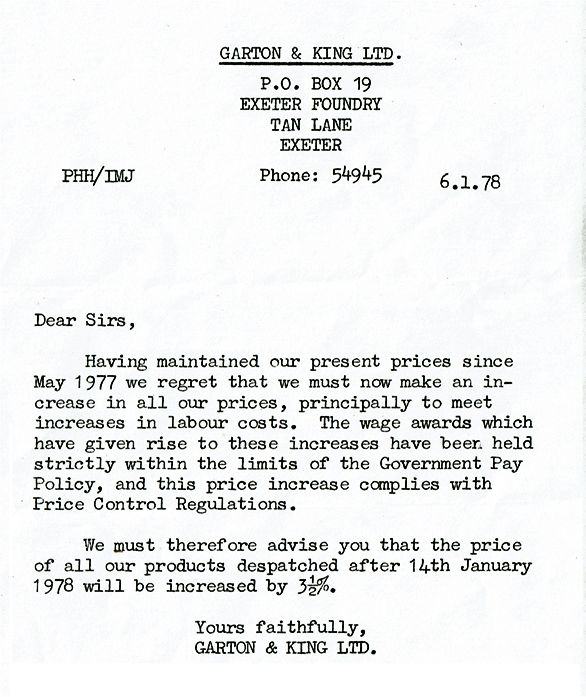

| Letter 1, 15th March 1974 | Letter 2, 2nd May 1977 | Letter 3, 6th January 1978 |

It was beginning to be apparent that the costs of operating a foundry, especially one far removed from the natural centres if British Industry was having an effect on the viability of the Tan Lane Foundry. In May 1977 another circular was produced stating that as the price of Foundry Coke and other Fuels was increasing, as were the costs incurred in carriage all commodities in and out of the Foundry as well as rising Overheads, Rates and National Insurance the company felt compelled to increase the cost of all Foundry Products by 7½%. The increase was to be effective from the 11th May 1977 (Letter 2).

It would seem that the second notification of price increase needed yet another change as shown in the third circular which was issued barely 8 months later on the 6th January 1978. Prices on all products was to be increased by 3½%, attributed to the rising Labour Costs, the increase to take effect on all products despatched after the 14th January 1978 (Letter 3).

Those of you who have read either on this website or in a hard copy Golden Hammer will note that in Chapter 10 there is much detail written about the Foundry Closure and why a possible 2 – 3 year Improvement Programme, whilst initially confidently supported, was abandoned; as a result of the examination by the Directors of the data compiled by Peter Holladay, it was agreed that there wasn’t a sufficient market available that would support such an Improvement Programme.

So, by Christmas 1977, with the failure to find a suitable entity to amalgamate with and a likely sale frustrated when it was discovered that the main negotiator was an undisclosed bankrupt, inevitably Redundancy Notices were issued. Further reading of Chapter 10 will provide more detail.

To complete the history of the Tan Lane Iron Foundry Site I can now refer to two documents, one was a Statutory Declaration confirming the realignment of the Public footpath (as seen on the plan at the top of this page) and signed by my father, and the Conveyance dated the 5th October 1979 confirming the sale of the property, which included the realigned footpaths on the east and south of the site, to, in the first purchaser the Sun Alliance and London Assurance Company and in turn to the second purchaser, Willment – Lescren Developments Limited of Isleworth Middlesex. The sale of the site for the sum of £80,000 brings to an end the forty one year ownership of this property by Garton & King Ltd but with the benefit of a slight increase of value to the original £550 paid to the Great Western Railway for the site in 1938.

Footpath Realignment Declaration 1979 |

The Conveyance to the new owners in 1979 |

I was able to discover that after closure the Foundry was demolished by Barry Olds Demolition & Salvage probably about 1979 / 1980. Although this former Exmouth Company still trades as Demolition Contractors, there are unfortunately no images of this event. I have spoken to Barry Olds who informed me that the task proved to be far more involved than was first thought and additional equipment had to be brought in to break up and remove the thick concrete rafts that were constructed back in the late 1930s to avoid subsidence.

Virtually no evidence of the site’s former use now remains, as is shown in the uppermost colour image on this page

Readers who worked for the company at Tan Lane or those that are just generally interested in the Works Layout (as planned by Henry Holladay and his father and drawn out by F.W. Beech (Architect & Surveyor) A.R.I.B.A. in July 1938) can view the enlarged drawings.

Site-plan - Floor-plan - Elevation-plan

I welcome any comments or observations. I would greatly appreciate sight of any photographs of the Works taken at Ground Level at any time in its existence – see the About Me page for Contact Details.

Updated June 2024

Top of Page

See also:

Birds Eye View — Map

Waterbeer Street Foundry — Workplace

High Street — Taylor & Bodley

Sitemap / Contents