If this complete Website was transformed into a physical Book then this page would be the End Page or Back Page.

Gradually, over many years, details, facts, memories, recollections and indeed explanations have been sent to me and I now have a small accumulation of these. Some of the explanations refer to processes, usually in more detail than on the relevant web page. Contributions include those given by members of the Holladay family; others have arrived by email or occasionally by letter from former staff members (or their family members) or from customers, and some through Guest Book entries. Information that shines a more personal light on otherwise mainly factual records that are part and parcel of the website Chapters. Often these observations give the reader valuable first-hand, sometimes intimate, occasionally humorous details of experiences, practices and incidents gained by the writer when employed by the company. Most are first-hand.

Some viewers of this page may be put off by the large amount of text but it is worth checking out whether your device allows you to enable ‘Read Aloud’ so you can sit back and listen – and, I have to say, snigger occasionally as to the way certain words are pronounced, or mispronounced. Sometimes I have given a link to a website page or pages.

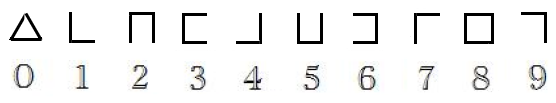

The first of these ‘snippets’ refer to a code system that may appear on the website. It was not always considered appropriate to show prices in internal estimates and memos. Detailed costs were considered confidential, so the Pounds Shillings and Pence were written using a Numeric Code, Here is the Code, the top line being the symbols used and below the numeral.

The article was based on an interview with Terry Jackson, universally known, with his wife Audrey, as the founders of Bernaville Nurseries, just outside Exeter on the Crediton Road.

Terry’s Grandfather William Jackson came from Yorkshire to become Foundry Manager for Willeys, he died just after the second world war. He was In his 80s.

Alf Jackson, his son and Terry’s father, had trained as a foundryman at Willeys with his own father but went on to work for Garton and King. Then moving on to be Foundry Manager at Huxtables of Barnstaple. When Alf’s elder brother, (also William) who was working at G & K had to give up foundry work because of dermatitis and became an outside representative for the Company Alf Jackson came back to G & K from Barnstaple to become the Foundry Manager. Alf Jackson’s Hillman Minx car can be seen beyond the Gears in the picture on the Homepage.

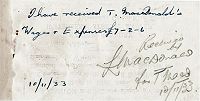

To be specific, Alfred Jackson was appointed General Works Foreman on the 27th September 1943 at a remuneration of £5.15.6d per week, also a yearly salary of £127 payable by four equal quarterly instalments.

With effect from the 1st June 1945 Alfred Jackson was appointed Works Manager and in place of the weekly and quarterly payments the total salary was fixed at £600.

Related pages: Personalities - Workforce at work

Tan Lane Foundry - Wheels and Gears

Hi,

I worked for Garton & King between 1973 and 77 in the office, as they paid better wages than I could earn when I first qualified as an Occupational Therapist. I worked as clerk, receptionist for Arthur Venn, who was in charge of the foundry and heavy machine shop & George who shared the office and his work. Every Friday they would walk off together with a briefcase, to collect the week's wages from the Bank on the Exe bridge roundabout. I also drew up the building plans for Mr. Henry for the central heating systems installed in such places as Castle Drogo and Killerton House (Mr. Henry reckoned my drawings were neater than his) and then Richard Baker would scribble all his specification over the plans and make a right mess of them .. she says smiling! It was an almost Dickensian office, with small offices half glazed, built round one large room in the middle, where Mr. Henry could see everyone and with a tube to send messages to and from the foundry and machine shop. Very much a step back in time.

Related pages: Tan Lane Foundry - Heating

Workforce - Workforce at Leisure

I wrote briefly on the Exeter memories site on Facebook - my granny, Margaret Rugg worked at Garton and King for many years as secretary to Mr Alec Holladay at the North Street Showroom. She remained lifelong friends with Gabby Holladay after leaving G&K. I remember visiting granny in the offices and her clacking away on the typewriter. She was very happy working there and always enjoyed going to work. I distinctly remember we only ever went to the Devon County Show when myself and my sister were young if granny was able to get free tickets from work! I also remember the huge dog that Mr Alec Holladay had. ['Judy' – RH]

Related pages: Aga (inc. North Street) - Personalities

Wheels and Gears (inc the County Show)

I have spent some time looking through your website and I have found some information of relevance to my family. My Grandad was called Frederick Leonard Thorn (July 1924 - Sept 2005) he was a Pattern Maker for Garton & King. His name appears on a list of employees you have from 1950. I have also discovered from your site that he was in the Sand Rats Skittles Team! In the photograph he is top row 3rd in from the left. I would be very interested to hear about what a Pattern Maker's job involved.

My Great Grandfather was also called Fred Thorn. There is a Thorn listed on the Timesheet dated July 1928 and on the Office Staff list of 1950 there is an F Thorn. Also, when I looked at the photo entitled Dinner at the Imperial Hotel 1953 my eye was drawn to a man standing at the back, 3rd in from the right. The list of names confirms it is my Great Grandfather. Having spoken to my Mum (daughter of F. L. Thorn) she thinks she has a photo from Garton & King's which belonged to my Grandad, she will endeavour to locate it for me soon.

She doesn't have any further information about the tape measure, she found it whilst clearing my Grandad's garage after he passed away in 2005. She thought my husband might like it as a little keepsake, as he is a tradesman and would probably appreciate it for what it was. We display it on a little wooden plinth in our glass cabinet and it does look rather nice!

I have a few examples of this tape measure - being no LTD alongside the Company Name makes them Pre 1925, "E.C." on the address of the Woodgate Press as a very early form of GPO postcode. Further research suggests that the E.C. (Eastern Central) postcode changed in 1917 so the Tape Measure dates from then or before.

Related pages: Workforce at Leisure - Workforce at Work

Third Rail, Handrail, Finials and Freebies

Yes I do remember Alf Jackson the Foundry Foreman. I remember the Smithy as well A short person who broke his shoulder when a boiler section pinned him to a wall, he lost a lot of weight while he was off work.

I remember

The electrician with the Sunbeam Motor bike.

The AGA salesman who lived next door to my Aunty in Myrtle Road (St Thomas) I think it was.

Albert Saunders the Foreman.

Jim Matthews, Albert's mate.

Before getting married I lived at 23 Greenway off Dunsford Hill St Thomas. I started work at Garton and King around July 1961 till 1965. My boss was Albert Saunders at Tan Lane. I can remember George Richardson and Matthews. A few others I can remember how they looked but not their names.

Related pages: Aga - Heating - Workforce at Work - Workforce at Leisure

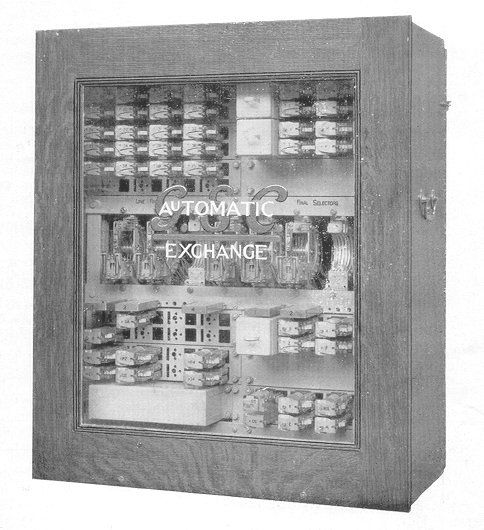

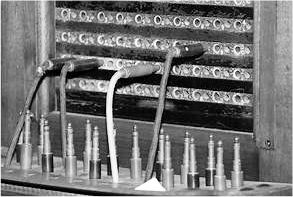

The Tan Lane works had two phone systems: the switchboard system - originally the old plug-in exchange in its own cubicle on the left as you entered the office, later replaced by the desk-top switched unit on the desk in the first typist's office.

Then the automatic dialled internal phone system - some desk models, some wall-mounted, on which it was possible to replace the receiver wrongly, which made that extension unobtainable - although that didn't cut off the whole system.

He [Rory Parsons] worked in total 49 Years with Garton & King. He started in the foundry [a pipe fitter in the heating dept., which was based at the Tan Lane foundry] and then worked with Mr Alec Holladay. He worked with the company when Garton King Appliances were formed and afterwards.

Related pages: Aga - Heating - Personalities - Workforce at Work

Arthur G Venn was a very tall lean man, who had a wicked sense of humour, however he once talked of when he was a navigator on a ship during the war that was sunk, he described how he hung to wreckage, during the night & heard nearly everyone around him succumb to sharks or drowning, he explained that he was one of the few who survived and were rescued - and then went on to say how at the time he'd been off duty when they were torpedoed and so when he was picked up by another Navy ship, only had his vest and shorts to his name: he hadn't been very long on the ship when he was summoned to the bridge, as their navigator had become ill and the Captain had asked if there was another on board - however when he saw the state of Arthur, he rounded on him and demanded HOW could he have the temerity to report to him in such a sorry state!!!??? Arthur smiled, as he recalled the Captain's face when he was told why Arthur was on board and how quickly the Captain managed to get him fully kitted out! I haven't a clue as to which ship he was on, but I guess it is far more than a tall story?

And not forgetting Julie Cowie's take (and maybe seconded by others) on Henry Holladay:-

Your father was very frugal where business expenditure was concerned, I remember when Wendy, who did the accounts questioned why he had written down the 2 Vauxhall Vivas (not sure of the model) over 10 years and not 4, he explained that, that was as long as he expected them to last!

There was a photocopier which involved a pink shiny sheet, he would put anything he wanted copied in the in-tray, bin underneath, out-tray to the other side .. all as you would expect; however the machine was quite fickle and on a bad day could scrumple the end result, I suspect that Mr. Henry knew this well from the rare occasions he might have used the machine himself .. and it used to make me smile when I saw him regularly counting the pink sheets in the bin and checking that they tallied with the finished copies .. and I admit that I did on more than one occasion, smuggle the odd pink sheet out of the office, just in case he checked the bin!!

The end of the month was always a bit of a nightmare, both he and Wendy were dedicated to balance the books and pay all bills ... and of course down to the last penny, nothing unusual about that in business practice - but not so easy back then - with only the aid of an adding machine, it would take Wendy and myself sometimes 2 or 3 attempts, Wendy would go through them all, once in ascending order the 2nd in descending order, any discrepancy and we would go through the invoices one by one checking them off against the 2 adding machine strips, once we'd found the missing/extra penny, the print-run for the cheques could be set up, printed, put in the envelopes, franked the following day!

He was also very careful not to waste paper, his handwriting was very small and he would start any letter on the back of a letter received that he no longer needed, however when he had filled up one side, he would then write on the front, across the top, in between the typing, if it was double spaced, or down the side, round the bottom and back up the other side if need be - if he was running out of space he would write even smaller, which as he used a fountain pen sometimes did not make easy reading - as a final resort, he would start on a spare piece of paper, keeping tight to the top and then on finishing he would take his steel rule. place it close to his last line and remove the rest of the page, he's the only person I've ever known who could fit 3 lines onto a sliver of paper no more than 1.5cms deep! ... He had difficulty with when to use letters singularly or double and almost always would put one c where there should be 2, the same with s's and l's and vice versa; as much as I couldn't bear to type the words incorrectly; he never challenged me on my typing, however, not wanting to waste a sheet of headed notepaper, he preferred to cross out and add letters, spelt as he wanted them spelt.

The filing system was quite incredible, taken in the context of the pre-computer era that existed back then .. and the number and age of both blueprints and original files that were stored in the rooms above the machine shop (the floor was only single floorboards and so everything stored above had layers of fine foundry dust) yet I remember when Arthur (Venn) was off on leave one time and I received an urgent request in the post from Stein Atkinson Stordy for a replacement part (I think it was a large "gear" wheel) from about 75 years previously supplied - based on their reference No., I was able to find the original blueprint, detailed specifications (neatly stored in date order, slightly crispy brown and fragile, but perfectly legible), send off for quotes for the blank and get all the info back in time for Arthur's return .. and all by snail-mail!! Difficult to believe these days .. whatever happened to all those old blueprints however, did Peter return them .. or were all the machines redundant anyway??

Changing the subject slightly, the company used to purchase scrap cast iron: early one morning Arthur (Venn) went down to inspect and verify a delivery from some lads with a lorry load, he came back upstairs in seconds and made 2 phone calls, one was to Devon County Council road work stores, my memory says it was out at Okehampton, but don't quote me, as we had made an afternoon delivery of manhole covers out there the previous day, he asked them to check their stock ....... they checked ... no manhole covers .... so second call was to the Police ....I can still see Arthur's face as he was caught between chuckling/bemused that they'd not only stolen them and tried to sell them back ..in the timescale, but they'd broken them up, maybe hoping they'd not be identified .. despite not only all having Garton & King Ltd cast into them, so then only good for smelting down, starting again and leaving Arthur further behind on his deliveries!!

Related pages: The Stationery Cupboard - Transport - Was 1900 a Good Year?

Tan Lane Foundry - Municipal Castings

I remember the offices and even now can recall the smell that any visitor to the lobby and stairwell heading up to the offices would immediately notice as you entered off the footpath along Exton Road. There were images or something on the walls I think and at the very top was a waiting room with memorabilia I think hung up. I have never managed to source any internal shots of the offices at all, though I have a drawing as to how they were originally (in 1939) planned to be laid out.

Related pages: Tan Lane Foundry - Bird's Eye View

PHH comments on how Gears were made:-

All gears were made either from whole patterns or from multi-toothed segments. After the bed had been prepared the pattern segment was moved around by hand. Often as you can imagine they might finish up with part of a tooth and this meant adjusting the last few moves where accuracy was not thought essential. Another method was to make the teeth in cores."

This is talking about the method of making the sand mould for casting the large gears. The big gear moulding machine at Tan Lane was a horizontal arm rotating around a vertical pillar mounted at the centre of a large circular moulding box set in the foundry floor. Using a template mounted on the arm the moulder moulds the bare outline of the gear in the sand. A wooden pattern with say 6 teeth is then mounted on the arm at exactly the right distance from the centre and is lowered into the outline mould. You pack sand into the gap between the outline and the pattern to form the mould for the first 6 teeth, then carefully raise the pattern, move the arm round so that the pattern when lowered engages exactly with the last tooth just moulded - now pack the sand to form the mould for the next 5 teeth and repeat. The arm keeps the radius fixed and, if everything is done absolutely accurately, when all the teeth are moulded, the pattern should engage exactly with the very first tooth moulded. The arm was rotated by a handle and gear box. By mounting the correct gears in the gearbox, the moulder would know exactly how many turns of the handle were needed to move the pattern from one position to the next and provided care was taken to compensate for any slack in the system, should end up exactly right - this could be tested by a dummy run first before moulding started. But what if it didn't quite match?... When dealing with large slow moving gears, like for a waterwheel, mill etc. where the mesh between this gear and the next was not that tight, it would not matter too much if they had to go back and redo the last dozen or so teeth deliberately increasing or decreasing slightly the spacing to get a match.

The alternative way of moulding the teeth would be to make a core box which produced a section of the gear mould in hardened (baked resin) sand - each section might have a dozen or more teeth, and then place these cores in a circle to form the complete mould, using the arm to get the radius exactly right and to get the joints between the sections exact. Not easy!

Related pages: Wheels and Gears - Tan Lane Foundry - In the Foundry

In the Shadows (Taylor & Bodley)

A mould needs a core where there is some hollow shape or opening in the casting which cannot be conveniently be made part of the pattern. The core is made separately in a Core Box (a wooden mould, rather like making sand castles). Originally the sand used was mixed with a resin. The Cores were then baked in this oven to make the core rock-hard so that they could be handled and placed in the correct position in the main sand mould. This oven stood in the foundry at Tan Lane. The heater on top produced hot air which was then circulated by a fan to the two chambers below. You can see some cores loaded onto a stillage about to be moved in to the left hand chamber. The oven was eventually scrapped (around 1970) when the foundry went over to using sodium silicate and CO2 to harden the sand. This process was then used both for making the main moulds and for making the cores.

Related pages: Tan Lane Foundry - In the Foundry

A reception was held last night at Penwic, Spicer Road, Exeter, the home of the Chairman and Managing Director of Garton & King Ltd, Mr H.E.E. Holladay, when a ‘Regentone’ television set was presented to Mr F. Horwill, of 25 Wyndham Avenue who is Chief Clerk of the firm. The gift was made by the Directors and presented by Mrs (B) Holladay, the occasion being the completion of Mr Horwill’s 50 years with the firm.

Mr Holladay congratulated Mr Horwill on his long service and wished him happiness for the future. Replying, Mr Horwill, who was accompanied by his wife, recalled how he had seen the firm grow over the years to its present size. A number of his colleagues attended.

Related pages: Personalities - Workforce at Leisure

I recently met a former employee of G & K at the 20th anniversary of the founding by David Cornforth of ‘Exeter Memories’ in St Thomas, Exeter (April 2024). Unfortunately David is no longer with us but he helped considerably in the early days in the setting up of the www.exeterfoundry.org.uk website. Ray Sparkes commenced employment with Garton & King Ltd as an Apprentice Pipe Fitter on the 11th August 1962; he left the company in November 1967. Most of the information that follows is in a letter he gave me at the St Thomas gathering.

He wrote to say that his time with G & K Ltd, where he served his Apprenticeship, was ‘the most wonderful time’ – during his period of employment he experienced time with many sections of the company and he has listed some of the names of persons he worked with both in the Heating section and elsewhere. He recalls that it was his father, Ned Sparkes, who was at the time working as a storemen for the Machine Shop, that arranged an appointment that led to his being accepted as an Apprentice.

The names he recalls were: Albert Saunders (Heating section Foreman), Mike Saunders (senior apprentice), Jimmy Mathews (Fitter), Nigel Myers, Tony Beighton & Chris Jordan (apprentices), Rory Parsons (Fitter - mentioned on this page), ‘AGA Ashmead (described as ‘The Main Man to install AGAs, proper name not recalled), Fred Thorn (Patternmaker), Ron Roswell (responsible for maintenance on heating installations for Marks & Spencers' premises in Devon & Cornwall) and Arthur Venn (also mentioned on this page) in ‘the office.’

He further writes...

When no heating work was available we had to paint the factory; on one occasion I was painting the front apex and dropped grey undercoat on the Golden Hammer (seen in the enlargement, central to the lettering ‘Garton & King Ltd’).

In the morning we were all summoned into the office to be asked ‘Who painted the Hammer?’ I put my hand up and explained the reason and was informed that the Hammer was coated with gold leaf, which meant nothing to me at the time. Fortunately at that time Henry Holladay was in America and his brother, Alec Holladay, had the Hammer re-leafed in gold.

The period of no heating work went on so I asked if I could work in the foundry, this was granted and I recall that on some Saturdays castings were made of ‘AA’ Signs in aluminium; as I was a ‘biker’ I asked if I could cast little Esso key fobs with the last pouring which I sold for 6d (old money).

It is also recalled that Rory Parsons had a three wheeled Messerschmitt ‘car’ in which we travelled to Northam in North Devon on a Monday with all our tools and fittings and travelled back on the Friday as the distance was classed as qualifying for ‘lodge money’ and the only vehicle at the time that was a works vehicle was the Austin Ron Rowsell had!

The North Devon journey was actually to RAF Chivenor - working on Nissan Huts (so I've been told).

Related pages: Golden Hammer Sign - Heating Equipment

I was employed by Garton & King from April 1961 as an apprentice in the Heating and Domestic Engineering Department. I have attached a copy of my apprenticeship certificate. I spent six happy years working from Tan Lane under Albert Saunders, foreman of the heating department, other names I remember are Jimmy Mathews, Rory Parsons, Ron Roswell and ??? Ashmead; all fitters. I think there was another fitter whose first name was Reg. Apprentices I remember are Ray Sparks, Nigel Myers, Chris Jordan and I think Winston Dart.

Sorry, memories are a bit hazy, probably because I was only 15 years old when I started with Garton & King and my mind was on other things in the 60’s, like Flower Power, Woodstock, Peace and Love, The Vietnam War, The Apollo Moon Missions, and nobody had even heard of the internet. However I do remember queueing up in Albert Saunders’ office to collect our weekly wages. The money was in brown envelopes, I was always skylarking around with the other apprentices and one day snatched the lad's envelope in front of me and threw it up in the air. Albert’s office was a wooden partition section in the machine shop and the envelope went down a gap in the wall and couldn’t be retrieved at the time. I can’t remember the exact outcome but I did have a good telling off!

Another time the Heating Dept was a bit quiet and myself and two other Apprentices were giving the job of painting the building’s windows and doors. I won’t name the other two guilty parties but we were told to paint everything we could with battleship grey paint. Not understanding the importance of it we painted the Golden Hammer!! Albert Saunders was mortified and I believe we were dragged up to the main office and were severely reprimanded. I think the Golden Hammer was taken down and given a new coat of Gold Leaf.

I’ve got so many other stories of things that happened in those years, but perhaps I should stop there. All I will say is despite all the larking around during those 6 years I did actually learn a lot of engineering skills which served me well in later years and I had a successful engineering career the peak of which was working for one of the worlds largest distribution companies.

A.M. Beighton, June 2024

Related pages: Golden Hammer Sign - Heating Equipment

Michael Saunders left John Stocker boys school in 1958 at the age of 15, he did his apprenticeship as a Pipe Fitting Plumber with the company. Fellow apprentices were Winston Dart, Colin Wood, Gerald Hayward, Roy Parsons and Alan Ley. The foreman was Albert Saunders (no relation). Among the fitters were wartime soldier George Richardson and wartime RAF man Jim Mathews.

Michael Saunders left John Stocker boys school in 1958 at the age of 15, he did his apprenticeship as a Pipe Fitting Plumber with the company. Fellow apprentices were Winston Dart, Colin Wood, Gerald Hayward, Roy Parsons and Alan Ley. The foreman was Albert Saunders (no relation). Among the fitters were wartime soldier George Richardson and wartime RAF man Jim Mathews.

One of Mike’s fellow apprentices, Lloyd Grose, always talked of becoming a pilot and eventually left the firm to join the RAF. When Mike next met him he had realised his ambition and was a pilot with the Red Arrows display team on a visit to Exeter Airport.

Two other apprentices, John Fairchild and John Pike, both had breaks away from their training to do National Service. Mike added that this apprenticeship set him up for a career which eventually led him to appointments in an Oil Company, Exeter University, the RD & E Hospital and the Maintenance Staff at Exeter Prison.

Related pages: Heating Equipment

My father, Harry Commins, and his colleagues appear in the image taken in the Foundry (right hand of the three images on the In the Foundry page, and also on the Workforce at Leisure page in the image taken of the 10th September 1953 Dinner at the Imperial Hotel. He is seated at the far table two persons to the left of the gentleman with his arm on the back of the chair. (Click link to see names).

My father was employed by Garton & King from leaving school just after the end of the First World War until 1953. Employed as a Moulder and then Chargehand at the Waterbeer Street Foundry and ultimately was in charge of the department producing castings in brass and gun metal. On the closure of the Waterbeer Street Foundry he moved with them to their custom designed Foundry at Tan Lane just before the Second Word War (August 1939).

Those he worked with at Tan Lane he recalled when making Fridge and freezer units in gun metal and aluminium were Frank Pinfold and Stan Bolt, from whom he took over from when Stan died.

The firm had, he recalls, a fairly successful Darts Team and amongst the team were my Dad, Frank Pinfold and Bert Abdey, who later became a league champion.

During the war quite a few volunteered for the Local Defence Volunteers and later the Home Guard, they performed Fire Watching duties at night. I followed in my father’s footsteps into the foundry when I left school in 1947 but preferred a more open-air life and switched to the building trade after a couple of months. An instance I recall was going to Telegraph Hill to collect sand with my father, Bert Abdey and Stan Bolt. When the lorry was filled I diverted to look for whortleberries and wild strawberries! Hours of work when I first started were 7.30 am to 4 pm with an hour for lunch, men continued work until 5.30pm.

The names I recall were Alf and Bill Jackson (Managers) Peter Jackson (Pattern Maker), Percy & Dennis Drew (Moulders), Albert Sanderson (Manager for Hot Water and AGA), Bill Venn (Works Manager). Works outings were in August.

Related pages: Waterbeer Street Foundry — Tan Lane Foundry

In the Foundry — Workforce at Leisure

Chris Bosworth wrote to tell me that when living in The Strand, Starcross he entered employment with Garton & King on the 8th September 1969 as an Apprentice Pipe Fitter in the Heating and Plumbing Department and completed his training as a Pipe Fitter and he remained with the Company until December 1974.

According to my father’s (Henry Holladay) typewritten ‘Letter of Reference’ to the Registrar of the University of Exeter he stated ‘We have found him a conscientious workman and he has had a range of experience on various types of jobs and equipment, so that he should be able to fill any new job with satisfaction to himself and his employer.’ I believe I am right in saying that he was successful in applying for the position with the University of Exeter as some time ago I met and talked to Chris Bosworth and I feel he mentioned that period of his employment.

Related pages: Heating Equipment

Updated June 2024

Top of page

See also:

Sitemap / Contents